Sustainable Transportation

Combining the flexibility On ROAD with

THE sustainability and efficiency on rail

Decarbonizing transportation

TRUCTRIC aims to accelerate the shift to fossil-free transports

We recognize the urgent need to put an end to the carbon emissions caused by road transports, understanding that our ability to stop fossil emissions effectively will have an impact on generations to come.

TRUCTRIC provides a new innovative concept for effective combined transports. The sustainability of rail is combined with the flexibility of road – with seamless transitions there-between.

This way fossil-free end-to-end transports are enabled, providing substantial reductions of fossil emissions and energy consumption

Let’s solve The Problems

The better transport alternative…

Availability

Many companies striving for sustainable operations, still miss competitive fossil free transport options. Therefor we aim to make efficient Combined Transportation available to all.

Any trailer should be possible to send by train – without long road transports.

Low cost

Cost is important, but should not prevent smart sustainable transport decisions! We are committed to provide for low cost transshipments between road and rail. To this end we enable lower capital investments and operating costs regarding transshipment terminals and railway wagons.

Time & Speed

Time aspects are critical. We offer seamless transshipments between road and rail by fast and individual loading/off-loading of trailer as well as fast loading/off-loading of full trains. This provides for faster transports and for more efficient use of capital involved in the transport value chain.

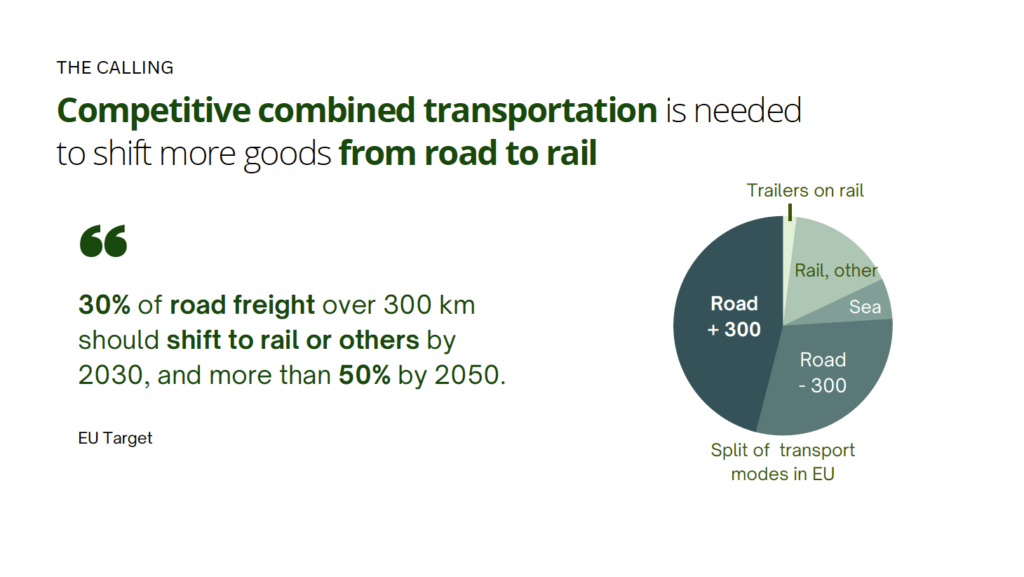

Competitive concept

Combined transports already today provide the best long-distance option for fossil free door-to-door transports, using fossil free vehicles. By improving the availability and competitiveness of Combined Transports we aim to provide a better option to long distance road transport and to be a catalyst for an accelerated shift to sustainable long-distance transportation over land.

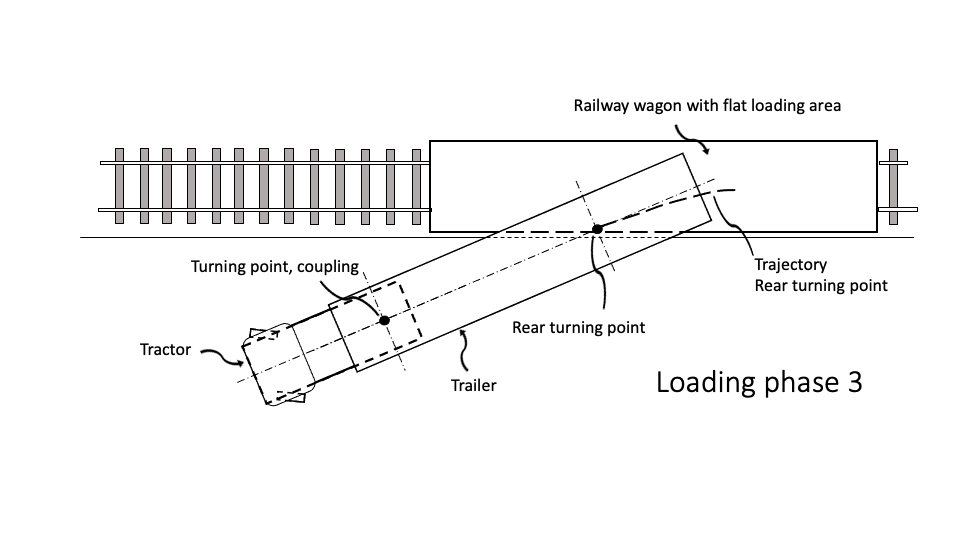

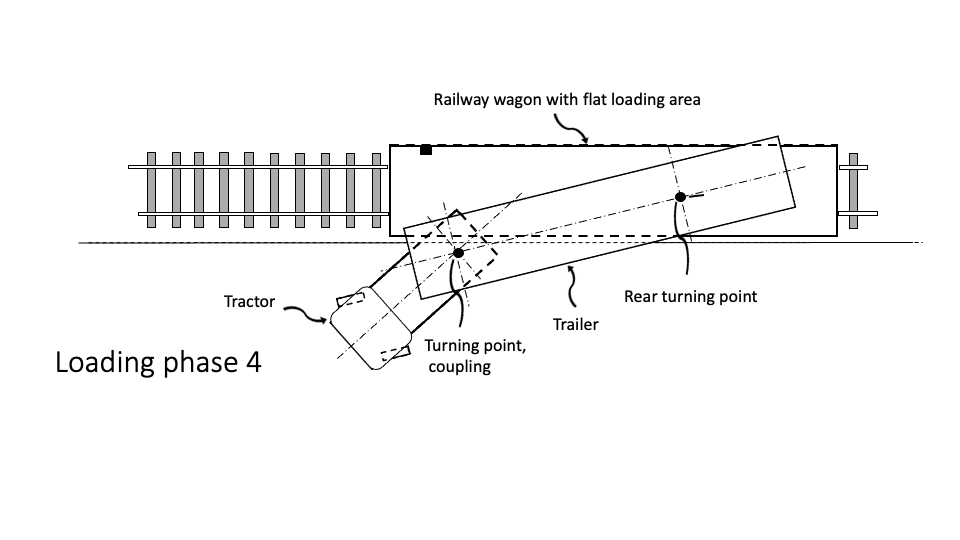

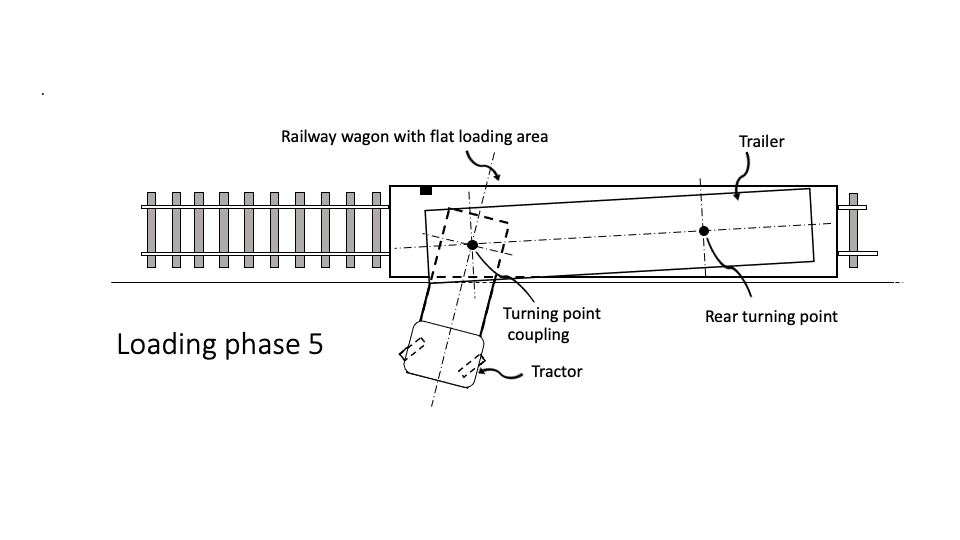

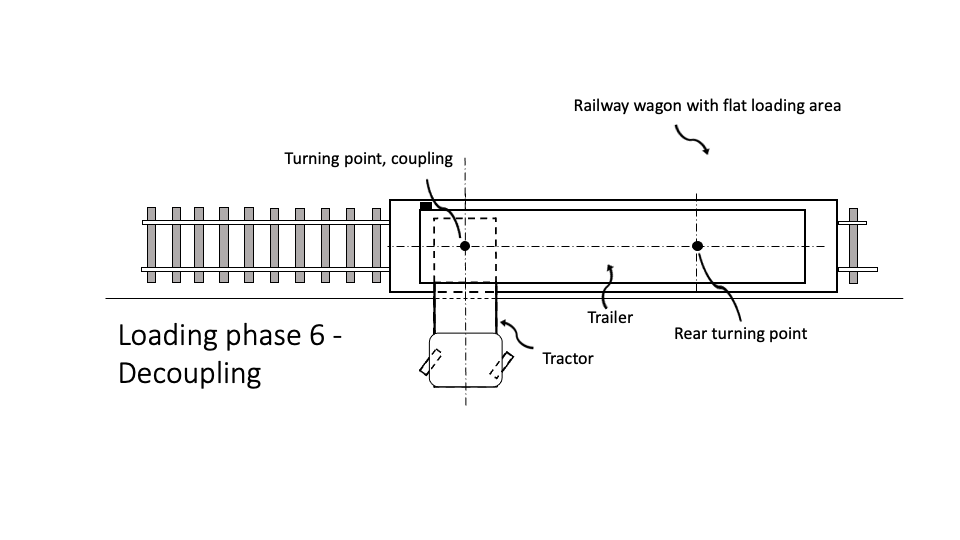

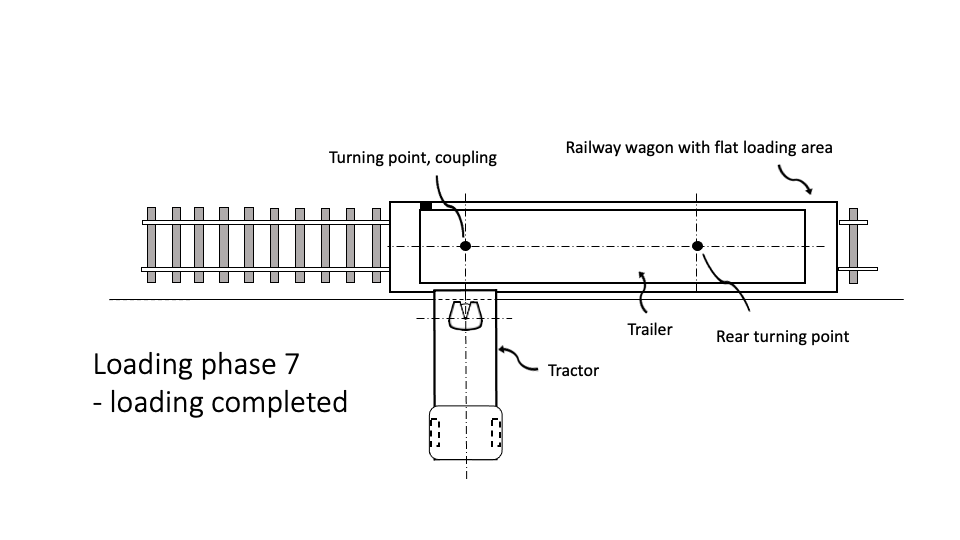

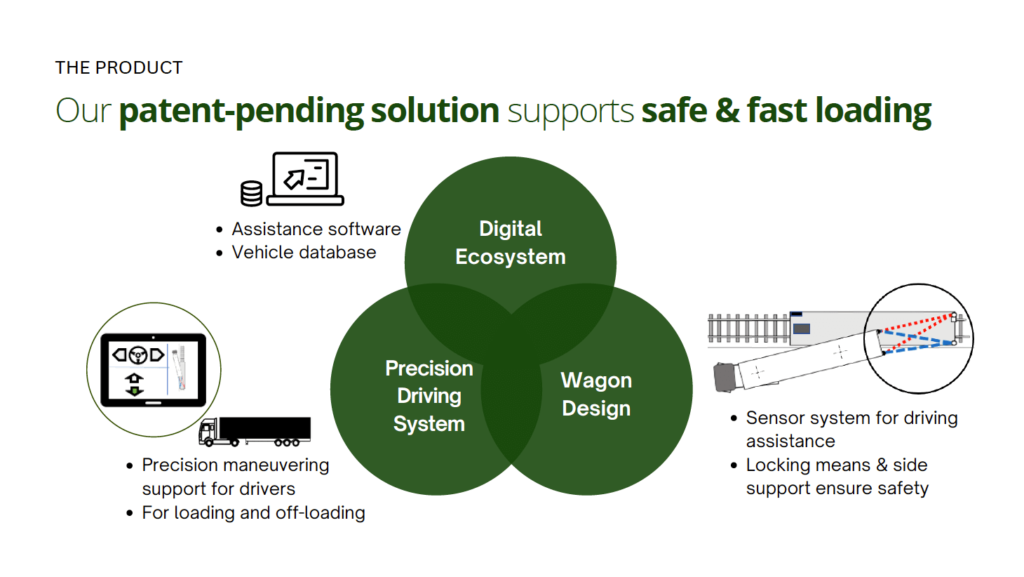

At the core of TRUCTRIC’s transshipment technology is our innovative RoRo loading concept, which is based on horizonal loading of semi-trailers directly onto flat railway wagons from the side thereof, using assisted precision driving. The loading is performed by a tractor pushing the trailer from an elevated platform beside the railway wagon. A driving assistance system secures correct positioning of the trailer during the loading procedure based on input from connected position sensors. The railway wagon is arranged with a flat loading area, for receiving the trailer and is further equipped to support and secure the trailer during loading and transport.

The background

Why Seamless Combined Transportation?

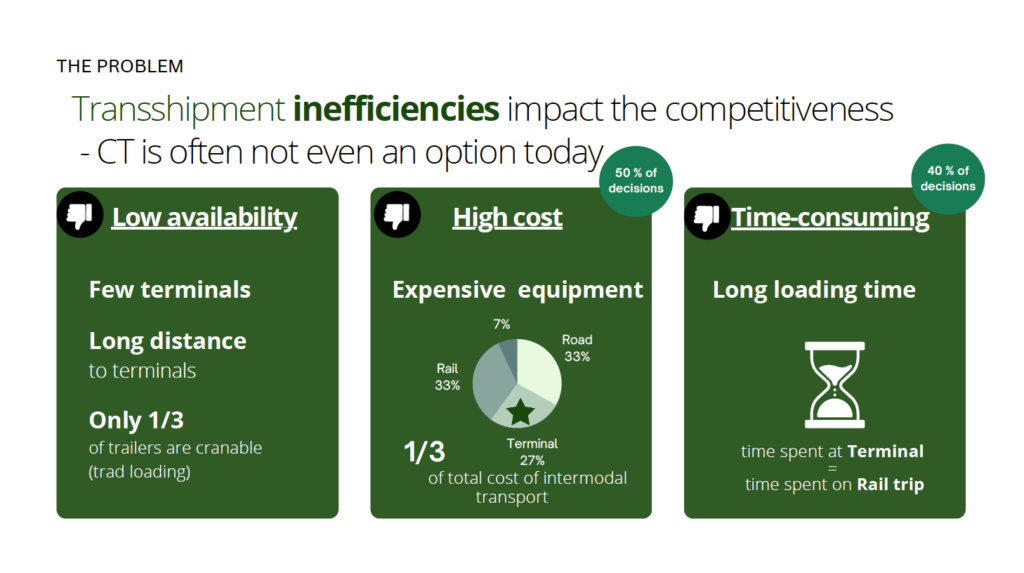

Unfortunately, presently Combined Transports are not for all. As transshipment terminals require large capital investments and thus also large traffic volumes, they become by necessity few and far apart. In many occasions terminals are too far away from either the start or the end of the transport or both. In addition most trailers cannot be shipped by train. Only a fraction, less than 1/3 of all trailers in EU, have the necessary reinforcements and lifting means that allow them to be loaded on a train with the presently dominating lifting technologies.

Costs for transshipment is unduly high. Did you know that direct cost is the key parameter in ca 50% of decisions on transport modes. According to Swedish research a large portion, almost 1/3 of a typical intermodal transport is related to costs at the transshipment terminal.

Also the time needed for transshipment is in many cases too high to be competitive. And time related parameters are key decision parameters in 40% of transport mode decisions. With present traditional transshipment technology, it takes relevant time to load or off-load on trailer. To load a full train with one or two cranes or reach stackers may take three to four hours. It is thus not unusual that a trailer spends as much or more time on terminals as is spends traveling on railway.

The technology

How does it work?

A tractor driver is provided with maneuvering instructions for fast, safe and precise loading of a trailer, via a screen inside the tractor. The instructions are provided by a driving assistance software, connected to the screen. The assistance software is also connected to a database, holding relevant information about the specific vehicles involved in a loading procedure, to adapt driving instructions accordingly. A sensor system is arranged in interaction between trailer and railway wagon, and connected to the assistance software to provide information about the position of the trailer in relation to the loading area on the railway wagon. The railway wagon has a fixed flat loading area and is equipped with means to support the and hold the trailer during loading and transportation.

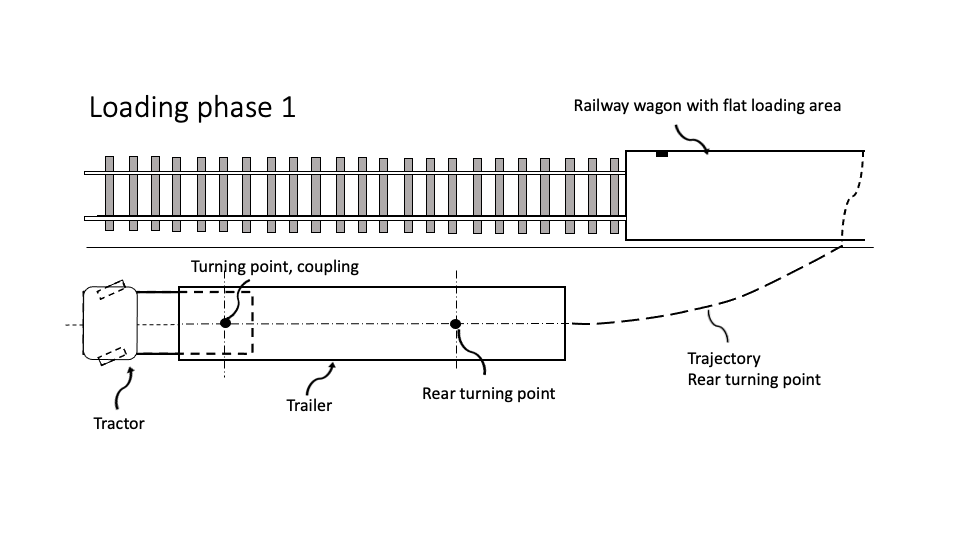

The tractor is reversed creating an angle with the trailer, bringing the rear end of the trailer to follow a trajectory towards the rear end of a loading area of the wagon

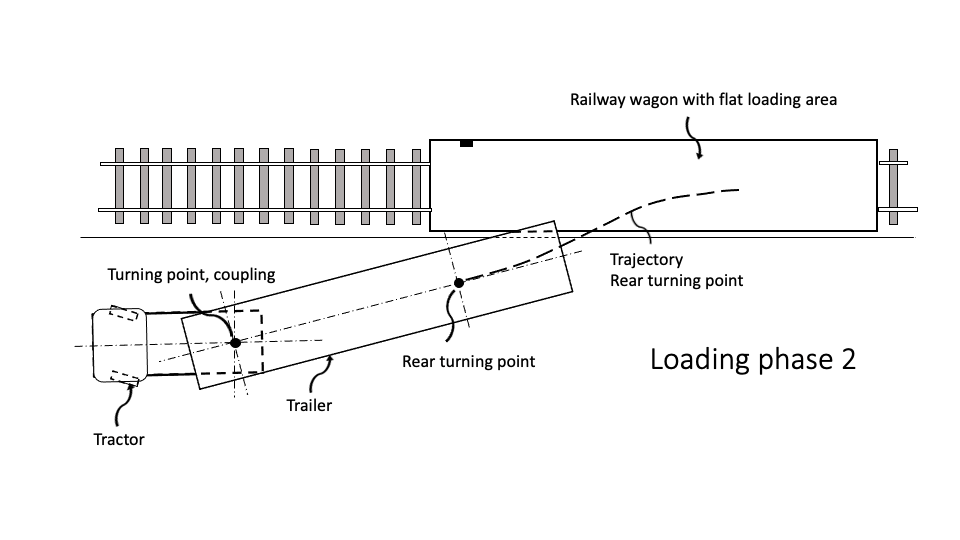

The tractor is reversed creating an angle with the trailer, bringing the rear end of the trailer to follow a trajectory towards the rear end of a loading area of the wagon